How is the piezoelectric effect used to generate ultrasound?

By Louise Møller Bierregaard and Malte Aarenstrup Launbjerg

Piezoelectricity is an electro-mechanical phenomenon found in certain asymmetric crystal structures such as quartz and various polycrystalline ceramics. When a piezoelectric material is exposed to physical stress, it will polarize and generate a voltage across its surface. This conversion of mechanical energy to electrical energy is known as the direct piezoelectric effect. Similarly, exposing a piezoelectric material to an electrical field will cause it to deform, either expanding or contracting, depending on the direction of the field. This is known as the converse piezoelectric effect. If exposed to an electric AC signal, the piezoelectric material will start to vibrate as it alternatingly contracts and expands, thereby emitting sound waves.

What is sound?

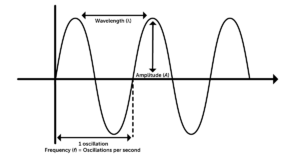

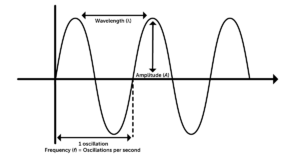

In essence, sounds are pressure waves emitted by a vibrating object. The number of waves produced in one second by a vibrating object is known as the sound’s frequency (f) and is measured in hertz (Hz). Thus, if an object emits 20 waves per second, it has a frequency of 20 Hz. To the human ear, sound frequency manifests as pitch. Higher frequencies result in high-pitch sounds like a whistle, whereas lower frequencies are perceived as low-pitch sounds like rolling thunder. The audible frequency range for a human ear is around 20 Hz to 20,000 Hz (20 kHz).

What is ultrasound?

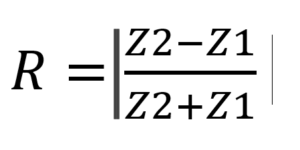

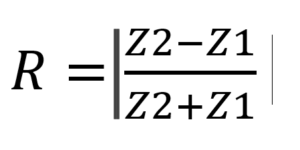

Sound with a frequency above 20 kHz is known as ultrasound. When propagating sound encounters a boundary between materials with different acoustic impedances (Z), some sound waves are reflected back (R) while others continue through. The larger the difference in acoustic impedance between the two materials is, the more waves will be reflected as

The amount of energy carried by sound is determined by the frequency and the amplitude (A) of the sound’s waves. As frequency and amplitude increase, so does the energy, and therefore ultrasound contains more energy compared to lower-frequency sound of equal amplitude, making it easier to detect for e.g., piezoelectric materials.

Propagating sound wave

How do piezoelectric devices generate and utilize ultrasound?

Piezoelectric materials can be made to vibrate via the converse piezoelectric effect to the point where they start emitting ultrasonic waves. At the same time, they can register mechanical energy such as sound and convert it into electrical energy by means of the direct piezoelectric effect. Devices that convert one energy type into another via one or both piezoelectric effects, are known as piezoelectric transducers. These devices enable a wide range of ultrasound technologies.

Ultrasound imaging in diagnostic medicine

Ultrasound imaging is used in several fields of diagnostic medicine. A well-known application is the ultrasound imaging of a human fetus inside a womb, carried out with scanning equipment enabled by a piezoelectric transducer. Before scanning commences, a lubricant is typically applied to the patient’s abdomen in order to improve between the scanner head and the skin tissue. Once applied, the transducer can start generating ultrasonic waves, emitting them into the body tissue. As the waves come into contact with tissue, bone etc., some of them are reflected back. The intensity of the reflections is contingent . The reflected waves are then registered by the transducer and converted into an electrical signal which can be used to generate an image of the womb and fetus. Matter with a high degree of acoustic impedance will appear brighter on the image as it reflects a larger portion of ultrasonic waves.

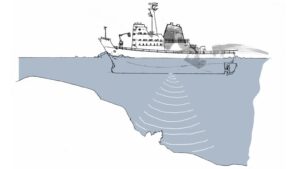

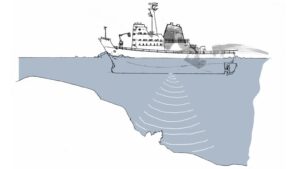

Ultrasound in underwater acoustics

One of the earliest practical applications of piezoelectricity was the underwater sonar (Sound/Sonic Navigation and Ranging). Originally created by French physicist Paul Langevin during World War I as a means to detect and combat enemy submarines, the core principles of the technology are still used to enable modern sonar equipment used in for instance fishing, seafloor mapping and underwater oil/gas excavation. As with ultrasound imaging, a piezoelectric transducer will emit ultrasonic waves into the water which will bounce of the sea floor and other underwater objects. Usually, a separate piezoelectric hydrophone, will register the reflected waves and generate an electrical signal used to produce imagery.

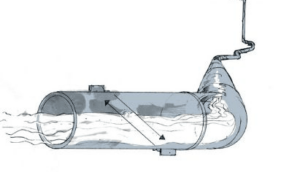

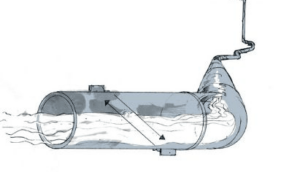

Ultrasound in flow measurement

Ultrasound can be used to characterize and measure the velocity, volume and/or mass flow of moving fluids and gases. Ultrasonic flow meters are immensely important to industrial flow systems such as water distribution networks and oil/gas pipelines since they are capable of immediately detecting system malfunctions or leaks. Two common ultrasonic flow meters are the Doppler flow meter and the transit time meter (also known as a time-of-flight meter). The Doppler flow meter utilizes a piezoelectric transducer to emit ultrasonic waves into the flow and subsequently register their echo as they collide with particles or bubbles in the fluid. Due to the relative speed of the particle, the frequency of the reflected wave will shift – this is the Doppler effect. The piezoelectric transducer can then determine the state of the flow based on the discrepancy in frequency between the emitted and registered wave. The transit time flow meter, on the other hand, employs two transducers placed diagonally to the direction of the flow. The transducers operate alternatingly as emitter and receiver. Due to the superposition of sound propagating speed and flow speed, the ultrasonic waves will travel faster when moving in the same direction as the flow, and slower when moving against it. By comparing the upstream and downstream transit time of the waves, the state of the flow can be determined.

Non-destructive testing

In non-destructive testing, ultrasound is used to (as the name suggests) test various materials such as plastics , ceramics and metals (in particular weld joints) for potential defects and flaws without damaging or destroying them in the process. The procedure involves exposing the test material to ultrasonic waves, subsequently registering and analyzing either the waves that passed through the material or the waves that were reflected by it. As the ultrasonic waves react to boundaries between mediums with different acoustic impedances, small cracks and pockets of air that could compromise the integrity of the material can be detected.

Ultrasound in actuator applications

Certain ultrasound applications only require the piezoelectric transducer to function as an emitter of ultrasonic waves and not as a receiver. Piezoelectric devices solely designed to produce ultrasound via the converse piezoelectric effect are called actuators, and they are used in various technologies across several industries.

High-Intensity Focused Ultrasound (HIFU)

HIFU is used in therapeutic medicine to perform non-invasive surgical procedures. A piezoelectric lens, typically made of a polycrystalline ceramic material such as PZT, will converge beams of powerful high-frequency ultrasound onto a pinpointed location inside the human body in the same way a magnifying glass converges light beams. This is a common way of ablating kidney stones into smaller pieces so they can pass through the bladder, but HIFU has also seen increased use in early-stage tumor treatments. In addition, HIFU is becoming an increasingly more popular choice for dermatological and cosmetical procedures, capable of smoothing out wrinkles and tightening skin.

Ultrasonic welding

Ultrasound can also be used to weld together plastics as absorption of the high-energy waves will cause the joint parts to melt. It is even possible to weld together metals using ultrasound without having the materials reach their melting points. Instead, the welding occurs as surface oxides of the metals disperse under high pressure.

Ultrasonic cleaning

Ultrasound is often used to clean and maintain small and intricate objects such as delicate machine parts or jewelry that would not be able to sustain more common methods of cleaning. The procedure involves lowering the object in question into a cleaning liquid which is then exposed to ultrasonic waves generated by a piezoelectric actuator. The micro-bubbles in the liquid will start to vibrate under the effect of the waves and eventually separate the filth from the cleaned object without damaging its surface.

ENGLISH

ENGLISH